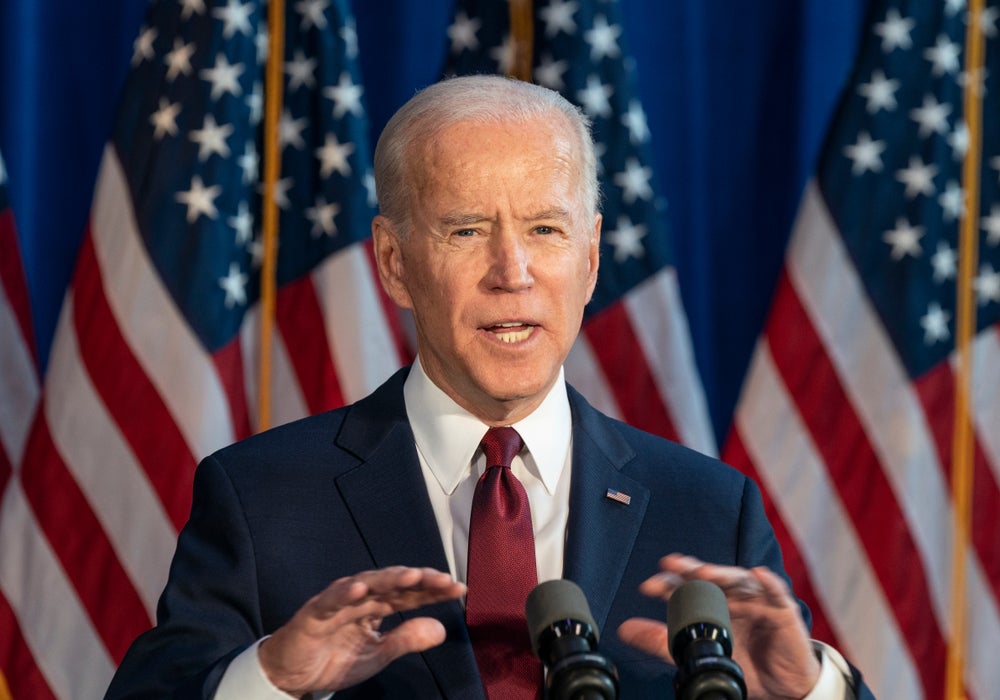

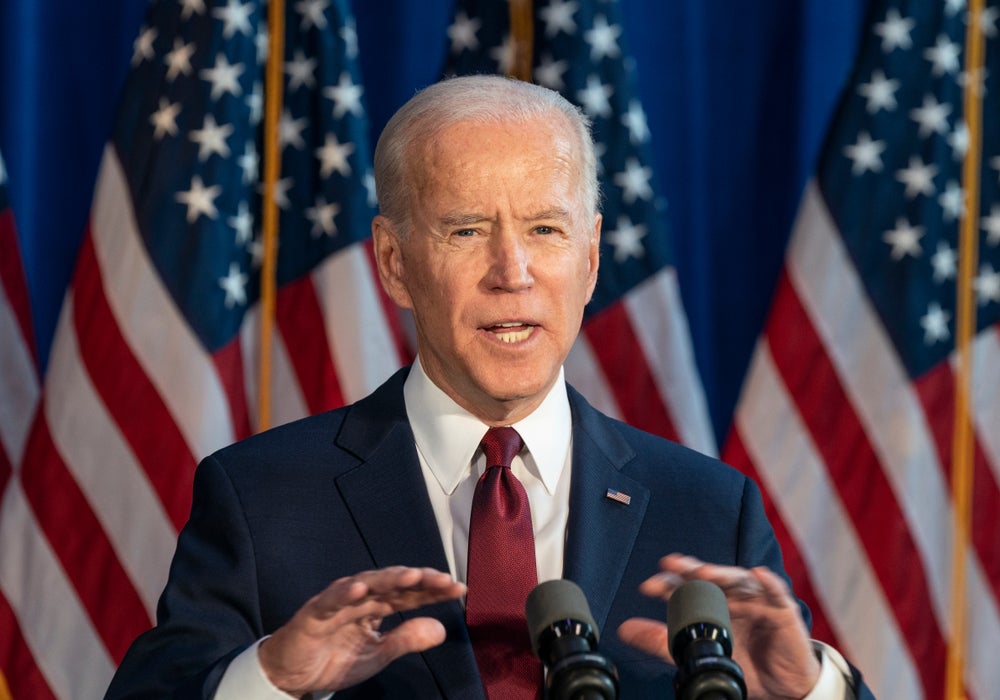

Liberty Justice Center and Pelican Institute challenge Biden’s LNG export ban

The latest legal action comes after 16 Republican states filed a lawsuit against the ban in March.

The latest legal action comes after 16 Republican states filed a lawsuit against the ban in March.

A new survey has found that over half of B2B respondents believethat “for most companies, ESG is just a marketing exercise”.

The oil & gas industry continues to be a hotbed of patent innovation. Activity is driven by the need for...

New report accuses fossil fuel companies of greenwashing, but profits are up

ADNOC partners with G42 and Presight to advance AI solutions for energy sector

SBTi gets into carbon offsets mess

“Britain has become more unequal” – Greenpeace on green transition tax